Thank you Kawboy, Biltonjim and Scotch for the tips! (in the posts reading order so I am not accused of favoritism, haha)

A separate thank you to Biltonjim for your very kind words, which added even more octane to my motivation

I'm glad I can contribute to the knowledge pull and also provide some entertainment.

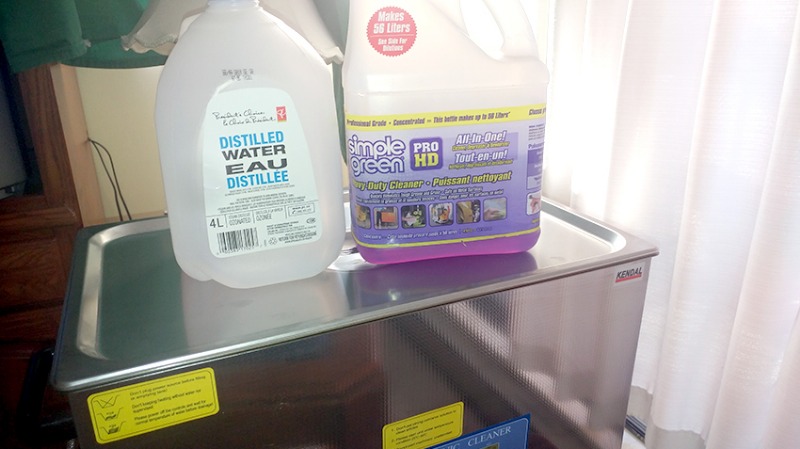

In this post I will just show what I am using for cleaning and securing.

I will start with 'my precious' - two pairs of reading glasses so I can come closer to all the details which need to be inspected and polished.

I use a combination of brushes, sand paper, picks and such, depending on the part and type of cleaning. The sand paper sometimes rough as 100 even, or 150. I find myself using 275 very often. Next step 600 and for things really fine, 1500 up to 2000. For aluminum I usually use brass fine brushes. For rough larger passages, like those coming through cylinder head cover with all the carbon inside, I used a piece of plastic tubing for electrical wires harnessing. I use Mother's aluminum polish, and Autosol general metal polish. My impression was that Mother's is more like a smooth paste and Autosol somewhat minimally abrasive, so I use Mother's for fine internal cleaning.

For a lot of parts I use an ultrasonic cleaner with Simple Green's Pro HD formula and distilled water in ratio roughly 1:5 or less. It cleans and removes grease very well. The 'green' formula of Simple Green is not advisable. The 'purple' formula is non aggressive towards aluminum and brass. I usually set the temperatures to about 55 degrees Celsius and time 15 minutes. Then I check the items and repeat. Usually 1 hour combined is enough. After cleaning I rinse everything in tap water, very through fully, and dry either with a hair dryer or place them on top of my apartment heater.

For general cleaning and penetrating I use WD40. But for very deep penetration of rusty stuck parts I use Kroil. I found it to be the best! WD40 had very little effect on the stuck pistons. I am sure that I accomplished having the cylinder block slide upwards (see my old post) thanks to Kroil. Acetone and Xylen - like paint thinner, I will soak parts in it as well, or use them for cleaning surfaces before painting.

For protection from rust after polishing things I use this aircraft anti-rust formula called ACF-50. I had to order it from Ontario. It's quite expensive, but a gallon will last for a very long time. It can be sprayed on electrical connections and metal. I read that it actually brings any traces of water or humidity to the surface instead of trapping it, and keeps parts form oxidizing for more than a year.

Last photo includes Seafoam - I use it as additive to fuel once in a while and it literally made the bike run smooth like new after being rough. This one is in spray, which I would spray for direct carburetor cleaning, but as additive to fuel they sell it in cans. I swear by it to work. In the past, I treated my Vmax like this: I disconnected the fuel pump and attached a small funnel to the fuel line. Then poured Seafoam until the engine died. Left it overnight, drained the carbs from Seafoam, repeated the funnel trick but this time with fuel to have it running followed again with Seafoam until the engine died. Left it overnight again. Drained the carbs, attached the fuel pump and let the engine run. Somoooth!!!! It felt like if the carburetor was rebuilt.

The other two in the photo are Aircraft paint stripper - I couldn't live without it for anything painted, and Metal Rescue. Metal Rescue is a bit expensive, about 35 dollars a gallon, but it lasts for a long time. It works until looses it's properties, so it can be reused several times. It's non-toxic, no acids, no alcalis, and environmentally safe. Looks like water, but it just makes rust to disappear like magic. First, before soaking, I always remove as much rust as I can mechanically with brushes and such first. Then soak the item usually overnight. Stubborn pieces I soak for two or three days. Then rinse with water and dry.