- Posts: 883

- Thank you received: 195

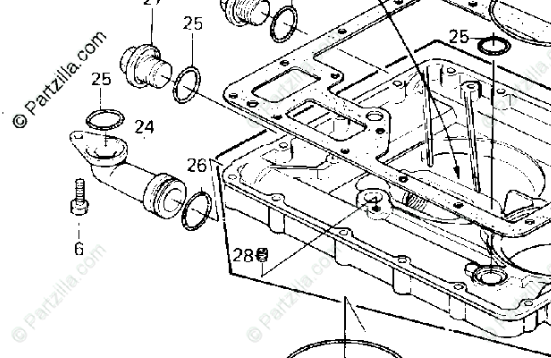

Technique to remove this part from oil pan? ELBOW,OIL PASSAGE 52014-1002

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Less

More

2 years 6 months ago - 2 years 6 months ago #30344

by dcarver220b

Technique to remove this part from oil pan? ELBOW,OIL PASSAGE 52014-1002 was created by dcarver220b

It's leaking past the o-ring. Thought it would be simple enough... remove the cap screw, wiggle the elbow free, install new o-ring.. badaBoom badaBing!

But noooo, it's in there tight. Took my water pump pliers, wrapped the jaws with electrical tape... Wiggle Wiggle... not.

Placed pliers are passage end, hit pliers with small ball peen hammer... Nope.

Decided to stop before I got to 'western' with it... Note the oil pan has been powder coated. Sure prefer to not drop the pan, as stuffing the header pipes into the collector is a sincere PITA...

#24 below

But noooo, it's in there tight. Took my water pump pliers, wrapped the jaws with electrical tape... Wiggle Wiggle... not.

Placed pliers are passage end, hit pliers with small ball peen hammer... Nope.

Decided to stop before I got to 'western' with it... Note the oil pan has been powder coated. Sure prefer to not drop the pan, as stuffing the header pipes into the collector is a sincere PITA...

#24 below

Last edit: 2 years 6 months ago by dcarver220b.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Less

More

- Posts: 883

- Thank you received: 195

2 years 6 months ago #30345

by dcarver220b

Replied by dcarver220b on topic Technique to remove this part from oil pan? ELBOW,OIL PASSAGE 52014-1002

Well, no replies. Gonna try again.

Please Log in or Create an account to join the conversation.

- Neville

-

- Offline

- Sustaining Member

-

Less

More

- Posts: 90

- Thank you received: 76

2 years 6 months ago #30346

by Neville

Replied by Neville on topic Technique to remove this part from oil pan? ELBOW,OIL PASSAGE 52014-1002

I assume you mean the "O" ring numbered 25 on elbow 24? - I replaced that "O" ring when I repainted my engine as I dropped the sump to clean the oil screen. I considered removing the elbow and replacing "O" ring 26 but the elbow was pretty much siezed in the sump - probably water/weather corrosion after 40 years of exposure. Sorry, but in my view the chance of breaking something and creating a more complex repair probably greater than the work involved in removing the exhaust and dropping the sump.

Always willing to hear other views though...

Always willing to hear other views though...

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Less

More

- Posts: 883

- Thank you received: 195

2 years 6 months ago #30347

by dcarver220b

Replied by dcarver220b on topic Technique to remove this part from oil pan? ELBOW,OIL PASSAGE 52014-1002

Yes, o-ring #25 and the one out back too. If I have too, I'll drop the exhaust. And if I do that, I'll pull the headers too. And if I do that I'll put in a new water pump mechanical seal. And send the the headers off for ceramic coating. Sure hope I can free the elbow up....I assume you mean the "O" ring numbered 25 on elbow 24? - I replaced that "O" ring when I repainted my engine as I dropped the sump to clean the oil screen. I considered removing the elbow and replacing "O" ring 26 but the elbow was pretty much siezed in the sump - probably water/weather corrosion after 40 years of exposure. Sorry, but in my view the chance of breaking something and creating a more complex repair probably greater than the work involved in removing the exhaust and dropping the sump.

Always willing to hear other views though...

Please Log in or Create an account to join the conversation.

- Kawboy

-

- Offline

- Sustaining Member

-

Less

More

- Posts: 3129

- Thank you received: 1098

2 years 6 months ago #30348

by Kawboy

Replied by Kawboy on topic Technique to remove this part from oil pan? ELBOW,OIL PASSAGE 52014-1002

Wondering if the oil pan got powder coated with the elbow in place and MAYBE the powder coating got locked in the joint? Try a little heat on the oil pan to soften up the powder coating maybe? It should be a slip fit but I'm thinking if it was powder coated as a single piece, the elbow might have got slightly rotated and that's why the joint is leaking. O-ringed joints typically don't leak. Standard o-ring compression is usually 15% of the thickness of the o-ring and will tolerate a lot before leaking.

The following user(s) said Thank You: biltonjim

Please Log in or Create an account to join the conversation.

- scotch

-

- Offline

- Sustaining Member

-

Less

More

- Posts: 1943

- Thank you received: 853

2 years 6 months ago - 2 years 6 months ago #30353

by scotch

1980 KZ 1300 sr# KZT30A-009997

Always High - Know Fear !

Replied by scotch on topic Technique to remove this part from oil pan? ELBOW,OIL PASSAGE 52014-1002

Have to agree that the possibility of breaking the elbow is very likely if it's "pounded-on" too hard. It's robust enough for it's intended purpose but it should be considered "brittle" , otherwise.

I can't believe that ANY powder coating business would do so with the elbow in place !

"Heating" not likely going to work as I believe powder-coating is baked at around 365F !

It's probably "stuck" due to corrosion and road-dirt !

If I were dealing with this: I'd cut a strip of cloth about 1" wide and 12" long and wrap it tightly around the elbow right-tight to the pan.

Then soak it liberally with ......YES....Lacquer-thinner and keep the "wrap" well soaked for a day. The idea being: the thinner will migrate and soften the O-ring considerably. Once softened it should allow the O-ring to pull through that which is causing it to remain stuck. At the very least, you should notice some additional movement which will indicate whether this "trick" is working and if so continue. Might take a day or two but I believe this should work.

Proof of concept ! Put an O-ring in some lacquer-thinner and see what happens to it with prolonged exposure !

I can't believe that ANY powder coating business would do so with the elbow in place !

"Heating" not likely going to work as I believe powder-coating is baked at around 365F !

It's probably "stuck" due to corrosion and road-dirt !

If I were dealing with this: I'd cut a strip of cloth about 1" wide and 12" long and wrap it tightly around the elbow right-tight to the pan.

Then soak it liberally with ......YES....Lacquer-thinner and keep the "wrap" well soaked for a day. The idea being: the thinner will migrate and soften the O-ring considerably. Once softened it should allow the O-ring to pull through that which is causing it to remain stuck. At the very least, you should notice some additional movement which will indicate whether this "trick" is working and if so continue. Might take a day or two but I believe this should work.

Proof of concept ! Put an O-ring in some lacquer-thinner and see what happens to it with prolonged exposure !

1980 KZ 1300 sr# KZT30A-009997

Always High - Know Fear !

Last edit: 2 years 6 months ago by scotch.

Please Log in or Create an account to join the conversation.

Time to create page: 0.136 seconds