- Posts: 883

- Thank you received: 195

CermaChrome first start - temperature reduction?

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Finally got the water pump installed and leak free

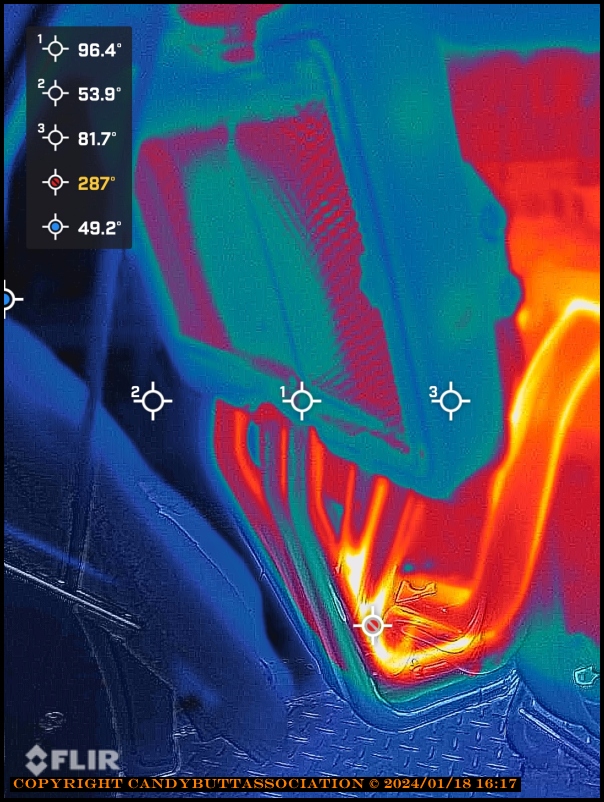

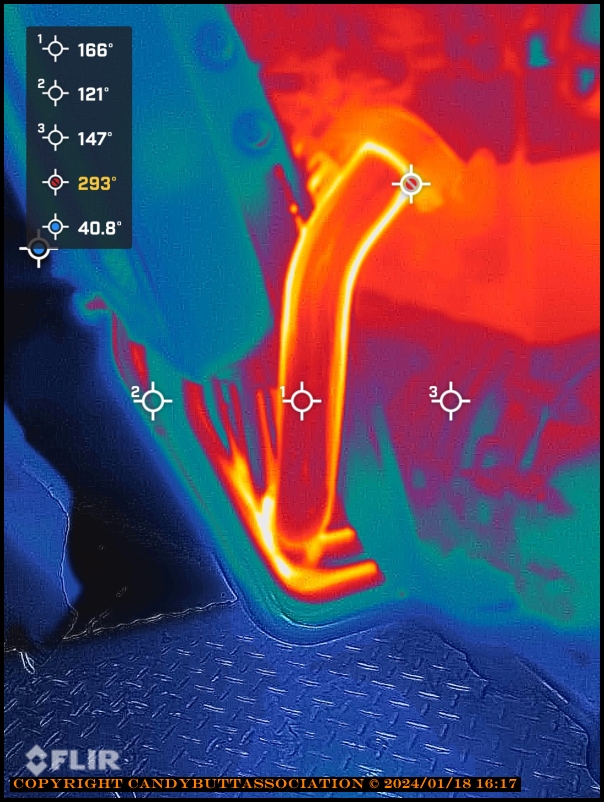

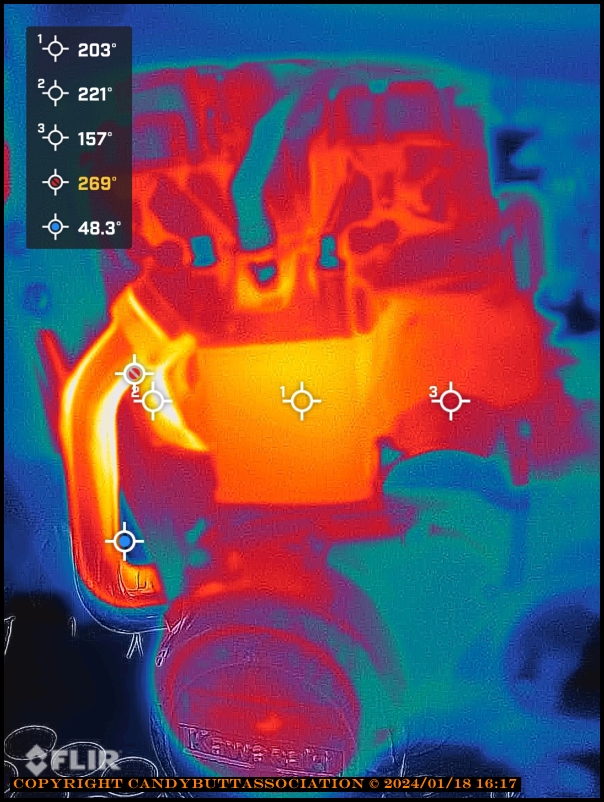

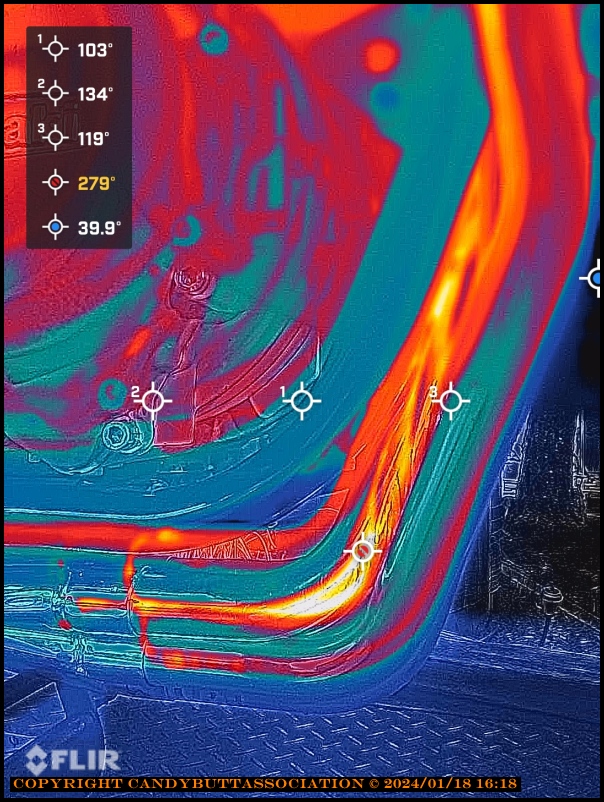

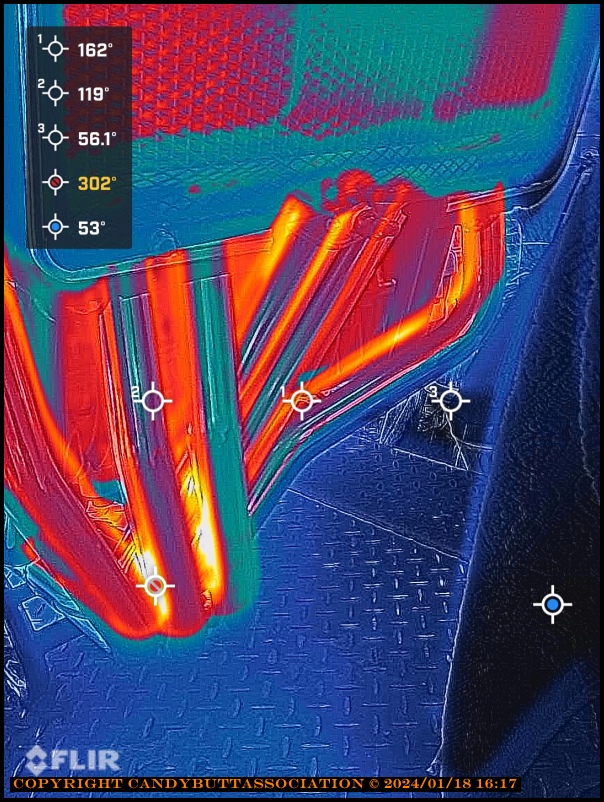

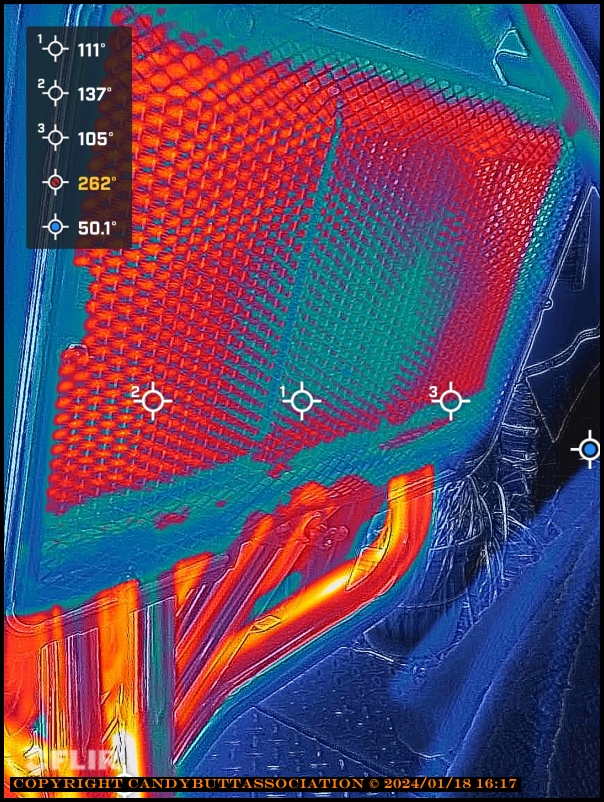

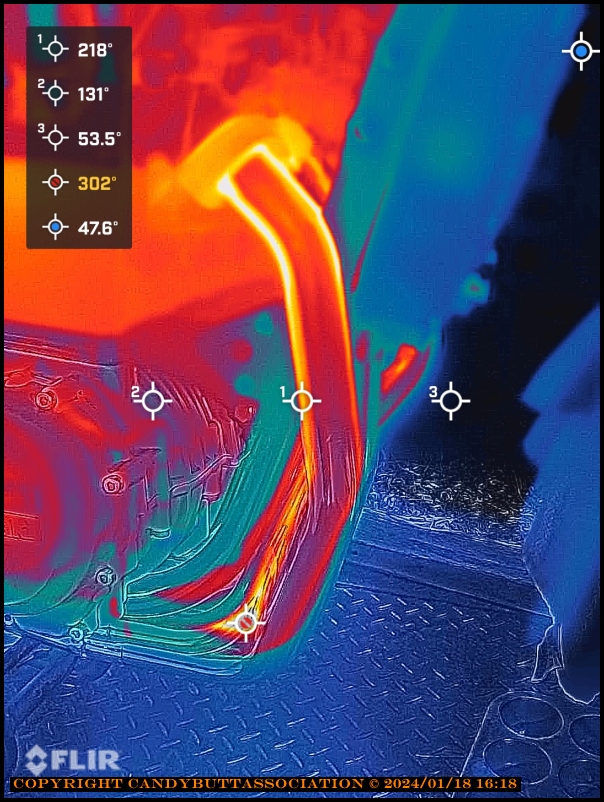

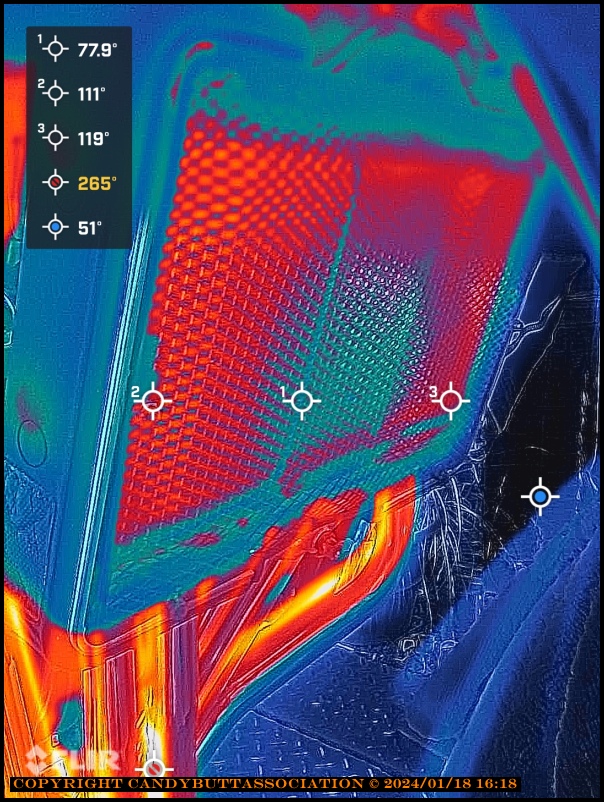

(I hope, haven't checked today yet!)Time to fire her up and see if the CermaChrome coating reduces heat onto radiator.As we all know, KZ's have marginal cooling. Removing OEM dual wall headers and replacing single wall pipes puts much more heat into radiator and engine block.

The legend identifies hot spot, cold spot and other temperature points.This quote from KawBoy, kz1300.com

The biggest issue I see with the KZ1300 is that the oil runs hot. The engine is massive in frontal size and sits right behind the exhaust down pipes and the radiator. dumping all that heat in front of the engine and of course the engine will run hotter.

The original stock exhaust was a double walled header pipe system and that would substantially help control the heat in front of the engine but almost all of the KZ's and ZN's have got replacement exhaust systems and the pipes are all single walled which will dump heat immediately in front of the massive engine block. You could use header wrap on the pipes but my personal experience with header wrap is that the wrap will absorb moisture during down time and that will prematurely rot out the exhaust pipes. I had to use it on my F350 Ford truck with 400 series stainless pipes and within a year and a half, I had perforated pipes.

I'm a bigger fan of ceramic header coatings since they will add corrosion protection and also keep a lot of the heat in the exhaust pipe until it exits at the tailpipe. Jet Hot coatings is one option and it's not cheap. Don just had his headers coated and once he gets the bike up and running, will be able to report on the effectiveness of having the pipes coated. I think he had Cermachrome- By Bright Hot Headers ( this is his topic)

Another DIY option is an internal ceramic coating offered by Eastwood's Internal Exhaust Coating Which I plan on trying. At $30 a can (which is enough to do the header pipes) it looks like an interesting option.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 883

- Thank you received: 195

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 883

- Thank you received: 195

Subjective statements about to happen. The area feels much cooler to the hand. The bike took much longer to reach mid-scale temperature.

Then again, ambient temp is high 50's low 60's. This imagery taken when primary purpose was to see if water seal leaked.Would be interesting to compare previous imagery to new. Less subjective.

Headed back up to shop in a bit.. Oh, also have the new fan installed. So that's changed too.

Please Log in or Create an account to join the conversation.

- Kawboy

-

- Offline

- Sustaining Member

-

- Posts: 3129

- Thank you received: 1098

Also wanted to mention that usually when using polyethylene glycol, the burping process is obvious because when air is trapped in the coolant and the coolant boils over because it's not circulating, you have to shutdown and burp the air out.

Evans has a boiling point of 375F and I suspect the "boil over" would not be evident. I have no experience with Evans coolant. Just sitting here thinking about Evans and the burping process. I could be totally out to lunch here. Just speaking out loud.

Then I also wonder- if Evans doesn't boil until 375F, will the cooling system even build up pressure??

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

- Posts: 883

- Thank you received: 195

Yes on first starts w CermaChrome. Also, wiped headers down to remove fingerprint oils that would burn into coating.Just a friendly reminder- Cermachrome instructions call for an initial warm up for 5 minutes then a shutdown, followed by a 10 minute warm up then shutdown, then normal service operating.

Also wanted to mention that usually when using polyethylene glycol, the burping process is obvious because when air is trapped in the coolant and the coolant boils over because it's not circulating, you have to shutdown and burp the air out.

Evans has a boiling point of 375F and I suspect the "boil over" would not be evident. I have no experience with Evans coolant. Just sitting here thinking about Evans and the burping process. I could be totally out to lunch here. Just speaking out loud.

Then I also wonder- if Evans doesn't boil until 375F, will the cooling system even build up pressure??

Evans - Click here, go to about 1 minute 20 seconds.

From Evans website "A different radiator/pressure cap is not required with Evans waterless coolant. A water-based coolant generally requires anywhere from a 7 to 15 psig pressure cap. Higher pressure raises the boiling point of water-based coolant. Evans waterless coolant expands slightly as it warms, creating pressure of 3–5 psig, and the existing cap does not need to be changed.

"Will using Evans lower the operating temp?

Typically no. Vehicles running under normal operating conditions should show either no change or a slight increase in temperature, but that will depend on cooling system configuration as well as driving conditions. In high horsepower applications, the temperature effect of running Evans waterless coolant will depend on the engine and cooling system components. Certain systems that use incompatible components, have an existing problem, or are poorly designed could run hotter. "

Not sure if I'll continue Evans use. It's butt hurt expensive, and, maybe, hopefully, the other work I've done has improved cooling to the point regular coolant can be used?

Please Log in or Create an account to join the conversation.

- Kawboy

-

- Offline

- Sustaining Member

-

- Posts: 3129

- Thank you received: 1098

All Ethylene Glycol or Polyethylene glycol has a lifetime limit usually around 5 years and needs to be changed out. Most people don't change their antifreeze and the consequences can be fatal. The PH level changes and that's the problem.

Most antifreezes are a blend of water and antifreeze and that too is a problem. Most people when / if they do change their antifreeze use tap water and who knows what the PH is of that water. they probably would be better off not changing the antifreeze at all.

All antifreeze products call for the use of deionized water for the blend, be it 50 /50 or 60 / 40 and some people think distilled water is deionized water.

Evans is a waterless product that's chemically stable and will never require changing out, so once put in the cooling system, forget about it. it can evaporate over time and its suggested that periodic level checks be done and suggested that top up be done with more Evans but if stuck in a pinch, you can add up to 3% water without any harmful effects.

After seeing the cylinder liners I pulled out of my cylinder block and inspecting, those liners are bare cast steel with no corrosive coating on them at all. I don't know how many wet sleeve engines use bare cast steel liners but I do know that if you were to opt for say the best of the best wet sleeves "Darton Sleeves" they come with a Phosphating coating for corrosion protection. Now that I know what material the liners are made of and seeing the fugglyness of the liners, I will not use a coolant other than waterless. and I understand that all antifreezes have corrosion protection but if there's something better out there and the price difference is $20, why wouldn't you switch??

At this point, 5 of the 6 cylinders have been roughly cleaned up (i.e. not completely) and they do clean up. My concern is that after 40K KMs they build up was about .030" thick and I see that as a thermal barrier. Not to my liking.

This one was cleaned up with a smooth flat file for about 10 minutes and it's far from being ready for installation as far as I'm concerned.

As removed from the cylinder block .Like I said "Fuggly"

Please Log in or Create an account to join the conversation.