- Posts: 3129

- Thank you received: 1098

Cylinder Machining / Plateau Honing / Piston Cylinder Tolerances

- Kawboy

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Less

More

1 year 2 weeks ago - 1 year 2 weeks ago #31722

by Kawboy

Cylinder Machining / Plateau Honing / Piston Cylinder Tolerances was created by Kawboy

I thought it was time we had a topic / discussion about piston cylinder maintenance, machining practices and fits and tolerances due to the fact that we have 40-year-old motorcycles with Operating / Service Manuals created 40 years ago and machining practices have changed but there have been no updates to our provided information for operating / maintaining our bikes.

Back in the 1970’s and early 80’s, cylinders were bored with a boring bar then finished honed to size with a “precision hone” which typically had two opposing 280 grit honing stones and two opposing guide bars. It got the job done leaving a reasonably true cylindrical finish. The cross hatching was on a 45 degree pattern and the surface finish was consistent with an obvious cross hatching pattern.

Along came the 1980’s and demands got placed on manufacturers to improve emissions. The manufacturers put on their thinking caps to try to come up with improvements to meet the new standards.First, they needed to understand what was the root cause of poor emissions and in the forefront was crankcase ventilation. Crankcases had to be vented of the blow by gases that escaped the piston / cylinder sealing, allowing unburnt gases into the crankcase which mixed with the hot oil fumes. Positive Crankcase Ventilation rerouted those gases back in to the intake to be burned in the combustion process and like a 2 stoke gas mix, the exhaust emission was higher than what was produced from burning just gasoline. How could they improve the piston / cylinder sealing?At the time, cylinder finishes were left moderately rough and needed to be “broken in”. Because of the roughness left by the honing process, the cylinder / piston clearance was left tight and instructions in the operating manual restricted engine operating rpm’s until the break in period was completed. During break in, crankcase gases developed was moderate and as the break in got completed, the gases developed got less.

There is a wealth of varying information available on many internet sites, magazines and aftermarket piston ring suppliers regarding break in practices but what if we could bypass all of those requirements and produce and engine you could run right off of the assembly line as if all that break in period stuff was done?So that was the goal and then they needed to figure out how to get there. The standard practice was to leave the cylinder with a moderately rough surface and then get the piston rings to break in the surface finish of the cylinder to leave a smooth surface for sealing of the piston rings to the cylinder. The end goal also needed to leave clearance room for an oil film to lubricate the sliding parts of the piston and piston rings on the cylinder wall without leaving excessive clearance.

So just what would a broken in cylinder look like?If you have ever tore apart one of these KZ1300 engines that had been broken in and looked at the cylinders, you would have seen a smooth bore with a shiny finish and what appears to be some cross hatching sort of underneath the smooth finish. What you wouldn’t have seen would have been the out of round dimensions caused by the major and minor thrust of the piston on the front and the back sides of the cylinder, otherwise the cylinder would be considered to be in great shape. A smooth shiny finish for the piston to thrust upon and a smooth finish for the rings to slide / seal on with grooves to hold an oil film in. Perfect.Well, if that’s “perfect” after break in, how can we achieve that before break in? We need To be able to produce that finish and leave enough clearance for the required oil film and that’s how Plateau Cylinder Honing came to be the standard practice so let’s dig in to Plateau Honing.

If you have ever prepped a previously painted surface for repainting and have done it right, you would have started with a rough grit sandpaper to flatten the surface and then progressed through finer grades of paper to produce a smooth finish to be painted. If you didn’t do it properly, your finished painted surface looked terrible as if it had sanding grooves underneath that freshly painted surface. Hold that thought for a moment.When prepping for paint, you would have sanded with maybe 100 grit until you had a even scratched surface that was flat. Next, you grab some 180 grit and remove all those deep scratches leaving a consistent flat surface with finer scratches and then again, found maybe some 400 grit to remove the 180 grit scratches leaving 400 grit, even finer scratches. Some would leave it at that and then paint, some would go even further and head to 600 or 800 grit before hitting the surface with paint. The goal here would be to have a super smooth finish with no evidence of any sanding marks at all.Now go back to the finish we had when we left some deep scratches in the metal and then we painted the surface and had a shiny painted surface with what appeared to be scratches underneath. Isn’t that what we said we wanted the freshly broke in cylinder to look like? Yes? So how can we achieve that in a machining process.

This is how Plateau Honing came to be. Plateau honing starts with an 80-grit stones to “flatten” the surface and leave 80 grit cross hatching marks in the surface. That’s followed up with a 280 grit honing stones to take off the highest peaks off of the 80 grit cross hatching, flattening those peaks. This second stage could take a few as 10 strokes of the hone in the cylinder. This is then followed up with 400 or 500 grit to make those flattened peaks super smooth for the piston and piston rings to ride on. Possibly 30 to 40 strokes for this process. Whatever it takes to remove the 280 grit cross hatching of the flattened peaks. What’s left to be seen is the deep 80 grit cross hatching with a super smooth almost mirror like finish for 90 % of the surface. What’s great about this process is we have an engine that can be run as if it was already broke in so no break in period required. The piston rings provided today have a lapped surface finish and are round to marry up with a mirror finished surface of a cylinder that’s round and an almost perfect seal between the cylinder and piston rings is obtained right from the fresh rebuild.

One thing we need to understand is the finished piston clearance. If we reference the Service Manual for “specs” we find some interesting information. First, all through the manual you’ll find many references to “Service Limits” and seldom any reference to “Clearance”. In this one particular reference to piston cylinder clearance, we find both service limits and clearances.

The cylinder has a service limit of 62.10mm maximum

The piston diameter has a service limit of 61.80mm

The piston to cylinder clearance is quoted at .031 - .058 mm (.0012” - .0022”)

If the piston is at service limit and the cylinder is at service limit we have a difference of 62.10 – 61.80 = .3mm (.012”)

We need to rethink the piston cylinder clearance quoted in the Service Manual. We have to remember that back when the manual was written, the cylinder machining practices left the cylinder with a rough finish and the rings had to “hone” that finish which removes material. So the clearance was purposely left tight. Now, if we Plateau Hone the cylinders, we have to leave a clearance for the oil film and expansion of the piston in the cylinder. Remember when I previously said “I know a few machine shops that won’t finish a cylinder with a .001-,002” clearance “? So they would finish to a .003" finish and then allow the piston rings to hone the final which probably removed another .002” off of the cylinder.

That would be a final clearance of about .005”.

So I would suggest if you plan on having a Plateau Hone job done, you should aim for .004- .005” of final piston cylinder clearance and call it a day.

I hope this info is useful to those looking at a rebuild and look forward to comments here. I wish we had the ability to update the Service Manual but in lieu of that, we need to be able to find info like this for reference and that’s why I write this.

KB

Back in the 1970’s and early 80’s, cylinders were bored with a boring bar then finished honed to size with a “precision hone” which typically had two opposing 280 grit honing stones and two opposing guide bars. It got the job done leaving a reasonably true cylindrical finish. The cross hatching was on a 45 degree pattern and the surface finish was consistent with an obvious cross hatching pattern.

Along came the 1980’s and demands got placed on manufacturers to improve emissions. The manufacturers put on their thinking caps to try to come up with improvements to meet the new standards.First, they needed to understand what was the root cause of poor emissions and in the forefront was crankcase ventilation. Crankcases had to be vented of the blow by gases that escaped the piston / cylinder sealing, allowing unburnt gases into the crankcase which mixed with the hot oil fumes. Positive Crankcase Ventilation rerouted those gases back in to the intake to be burned in the combustion process and like a 2 stoke gas mix, the exhaust emission was higher than what was produced from burning just gasoline. How could they improve the piston / cylinder sealing?At the time, cylinder finishes were left moderately rough and needed to be “broken in”. Because of the roughness left by the honing process, the cylinder / piston clearance was left tight and instructions in the operating manual restricted engine operating rpm’s until the break in period was completed. During break in, crankcase gases developed was moderate and as the break in got completed, the gases developed got less.

There is a wealth of varying information available on many internet sites, magazines and aftermarket piston ring suppliers regarding break in practices but what if we could bypass all of those requirements and produce and engine you could run right off of the assembly line as if all that break in period stuff was done?So that was the goal and then they needed to figure out how to get there. The standard practice was to leave the cylinder with a moderately rough surface and then get the piston rings to break in the surface finish of the cylinder to leave a smooth surface for sealing of the piston rings to the cylinder. The end goal also needed to leave clearance room for an oil film to lubricate the sliding parts of the piston and piston rings on the cylinder wall without leaving excessive clearance.

So just what would a broken in cylinder look like?If you have ever tore apart one of these KZ1300 engines that had been broken in and looked at the cylinders, you would have seen a smooth bore with a shiny finish and what appears to be some cross hatching sort of underneath the smooth finish. What you wouldn’t have seen would have been the out of round dimensions caused by the major and minor thrust of the piston on the front and the back sides of the cylinder, otherwise the cylinder would be considered to be in great shape. A smooth shiny finish for the piston to thrust upon and a smooth finish for the rings to slide / seal on with grooves to hold an oil film in. Perfect.Well, if that’s “perfect” after break in, how can we achieve that before break in? We need To be able to produce that finish and leave enough clearance for the required oil film and that’s how Plateau Cylinder Honing came to be the standard practice so let’s dig in to Plateau Honing.

If you have ever prepped a previously painted surface for repainting and have done it right, you would have started with a rough grit sandpaper to flatten the surface and then progressed through finer grades of paper to produce a smooth finish to be painted. If you didn’t do it properly, your finished painted surface looked terrible as if it had sanding grooves underneath that freshly painted surface. Hold that thought for a moment.When prepping for paint, you would have sanded with maybe 100 grit until you had a even scratched surface that was flat. Next, you grab some 180 grit and remove all those deep scratches leaving a consistent flat surface with finer scratches and then again, found maybe some 400 grit to remove the 180 grit scratches leaving 400 grit, even finer scratches. Some would leave it at that and then paint, some would go even further and head to 600 or 800 grit before hitting the surface with paint. The goal here would be to have a super smooth finish with no evidence of any sanding marks at all.Now go back to the finish we had when we left some deep scratches in the metal and then we painted the surface and had a shiny painted surface with what appeared to be scratches underneath. Isn’t that what we said we wanted the freshly broke in cylinder to look like? Yes? So how can we achieve that in a machining process.

This is how Plateau Honing came to be. Plateau honing starts with an 80-grit stones to “flatten” the surface and leave 80 grit cross hatching marks in the surface. That’s followed up with a 280 grit honing stones to take off the highest peaks off of the 80 grit cross hatching, flattening those peaks. This second stage could take a few as 10 strokes of the hone in the cylinder. This is then followed up with 400 or 500 grit to make those flattened peaks super smooth for the piston and piston rings to ride on. Possibly 30 to 40 strokes for this process. Whatever it takes to remove the 280 grit cross hatching of the flattened peaks. What’s left to be seen is the deep 80 grit cross hatching with a super smooth almost mirror like finish for 90 % of the surface. What’s great about this process is we have an engine that can be run as if it was already broke in so no break in period required. The piston rings provided today have a lapped surface finish and are round to marry up with a mirror finished surface of a cylinder that’s round and an almost perfect seal between the cylinder and piston rings is obtained right from the fresh rebuild.

One thing we need to understand is the finished piston clearance. If we reference the Service Manual for “specs” we find some interesting information. First, all through the manual you’ll find many references to “Service Limits” and seldom any reference to “Clearance”. In this one particular reference to piston cylinder clearance, we find both service limits and clearances.

The cylinder has a service limit of 62.10mm maximum

The piston diameter has a service limit of 61.80mm

The piston to cylinder clearance is quoted at .031 - .058 mm (.0012” - .0022”)

If the piston is at service limit and the cylinder is at service limit we have a difference of 62.10 – 61.80 = .3mm (.012”)

We need to rethink the piston cylinder clearance quoted in the Service Manual. We have to remember that back when the manual was written, the cylinder machining practices left the cylinder with a rough finish and the rings had to “hone” that finish which removes material. So the clearance was purposely left tight. Now, if we Plateau Hone the cylinders, we have to leave a clearance for the oil film and expansion of the piston in the cylinder. Remember when I previously said “I know a few machine shops that won’t finish a cylinder with a .001-,002” clearance “? So they would finish to a .003" finish and then allow the piston rings to hone the final which probably removed another .002” off of the cylinder.

That would be a final clearance of about .005”.

So I would suggest if you plan on having a Plateau Hone job done, you should aim for .004- .005” of final piston cylinder clearance and call it a day.

I hope this info is useful to those looking at a rebuild and look forward to comments here. I wish we had the ability to update the Service Manual but in lieu of that, we need to be able to find info like this for reference and that’s why I write this.

KB

Last edit: 1 year 2 weeks ago by Kawboy.

The following user(s) said Thank You: biltonjim, dcarver220b, kawaBCN

Please Log in or Create an account to join the conversation.

- dcarver220b

-

- Offline

- Sustaining Member

-

Less

More

- Posts: 883

- Thank you received: 195

1 year 2 weeks ago #31725

by dcarver220b

Replied by dcarver220b on topic Cylinder Machining / Plateau Honing / Piston Cylinder Tolerances

This info captured, printed, saved to my holiest of kz1300 manuals.

Thank you KB..

DC

Thank you KB..

DC

Please Log in or Create an account to join the conversation.

- dcarver220b

-

- Offline

- Sustaining Member

-

Less

More

- Posts: 883

- Thank you received: 195

1 year 2 weeks ago #31726

by dcarver220b

Replied by dcarver220b on topic Cylinder Machining / Plateau Honing / Piston Cylinder Tolerances

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Elite Member

-

Less

More

- Posts: 251

- Thank you received: 46

1 year 1 week ago #31728

by Tyler

1981 KZ1300

Replied by Tyler on topic Cylinder Machining / Plateau Honing / Piston Cylinder Tolerances

Excellent write up Kawboy.

There has long been a debate about the necessary surface finish for a cylinder after honing. In the 2 stroke word they managed to fit pistons and seat rings on mirror smooth chrome and nickle-chrome plating. Briggs and Stratton did it for decades that way. Yet engine builders would swear a corse hone was necessary or you could risk oil consumption. I never remember seeing a cross-hatch in a brand new OEM engine of any kind now that I think about it.

Some piston ring manufacturers will specify a surface finish and I would tend to follow thier requirements.

Another consideration is that the 1300, particularly the early ones had defective cylinder bores, they were put of round from day one, and some shops in an attempt to resolve oil consumption issues may have had better luck with a coarse hone. These bikes were usually rebuilt and I don't know if the dealer SOP was to re-hone and ring or bore the cylinders and fit oversized pistons. While this was known issue in 79 I don't think any knows how common or rare it was. I suspect it may have been pretty uncommon.

There has long been a debate about the necessary surface finish for a cylinder after honing. In the 2 stroke word they managed to fit pistons and seat rings on mirror smooth chrome and nickle-chrome plating. Briggs and Stratton did it for decades that way. Yet engine builders would swear a corse hone was necessary or you could risk oil consumption. I never remember seeing a cross-hatch in a brand new OEM engine of any kind now that I think about it.

Some piston ring manufacturers will specify a surface finish and I would tend to follow thier requirements.

Another consideration is that the 1300, particularly the early ones had defective cylinder bores, they were put of round from day one, and some shops in an attempt to resolve oil consumption issues may have had better luck with a coarse hone. These bikes were usually rebuilt and I don't know if the dealer SOP was to re-hone and ring or bore the cylinders and fit oversized pistons. While this was known issue in 79 I don't think any knows how common or rare it was. I suspect it may have been pretty uncommon.

1981 KZ1300

Please Log in or Create an account to join the conversation.

- Kawboy

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Less

More

- Posts: 3129

- Thank you received: 1098

1 year 1 week ago - 1 year 1 week ago #31730

by Kawboy

Like everything else in life, if you've done something in the past and succeeded, you don't need guidance to do it again. if you buy a new motorcycle, why would you need to look through the Operating Manual to learn how to operate your new motorcycle? Turn the key on, place the engine kill switch to run, set the choke, pull in the clutch and hit the start button. When warmed up, rock off the main stand, pull in the clutch, select first gear and pull away. Done it before. it's a no brainer.

Operating Manuals and Service Manuals are used for reference only. Nobody ever pulls out a manual unless they need more information that they don't have in their brain at the time. It's the curse of present society. We have no time to learn things to the point that we have a new saying as of 10 years ago. Multitasking- the performing of more than one task at the same time. I believe that the oil consumption issues of the 1979's could probably be justified by improper break in due to not following the instructions in the Operating Manual, The dealers selling the 1980-1989 models probably told the new owners that if they didn't follow the break in period to the letter, that any oil consumption problems would not be corrected with warranty, so .......

Back in the 1980's, when cars and motorcycles left the assembly plant, they would have left with break in oil installed which is a mineral oil without any friction modifiers to give the piston rings and cylinders a chance to break in. Many owners who spent $4000 of their hard earned money on a new toy, would change the engine oil and filter in as little as a100 miles to put in the best engine oil of their choice and that could contribute to failed break in.

Some new owners might for shits and giggles, just run a new engine up to redline just to find out how powerful their new toy was and that may have caused a failed break in.

Then there are the guys who find information on the internet suggesting different "better ways" to break in a new set of rings by running up a fresh rebuild warmed up engine to redline and then cutting the ignition and waiting for the engine to go cool, then repeating that 3 more times, then driving it the way you drive it because the rings have seated.

So many ways to fail a break in and cause damage (seized pistons) or glazed cylinders that won't allow the rings to seat etc. Tyler talked about chromium cylinders and Nickel Composite cylinders which would have had cast iron rings. Hard cylinder walls need soft rings to properly marry up. Very common practice in 2 stroke engines at that time during break in usually included an oil rich mixture for the first tank full (20:1), followed with a normal oil/fuel ratio (40:1)

Aftermarket ring manufacturers have many different finishing processes on the ring sealing surface and they require different cylinder honing processes to be followed along with proper break in periods in order for the rings to properly seat, So it's critical that both the engine rebuilder and the operator follow a "best practice" for success - Machining Instructions and Break In Instructions.

Instructions are not guidelines. They are specific "To Do" step by step direct orders to be followed. They are developed during engineering processes when designing a new process. As an operator or operator maintainer of a piece of equipment, Operating Manuals and Service Manuals are dumbed down to give minimum guidance to the reader in order to achieve success and not overly complicate the information to the point that the information is overwhelming and won't be followed.

Back in my 20's, I was a licenced mechanic and I was good at what I did. I was fast, efficient and seldom ever have a comeback for rework. Then I got a job in nuclear and got exposed to a higher level of maintenance. We were also expected to have an understanding of the engineering aspect of the equipment that we worked on and from that point in my life and going forward, came to realize just how shitty a mechanic I was years before. I did good work but didn't know shit from apples about what or why I was repairing cars. Repairing cars - Break down Maintenance - an unacceptable maintenance practice in nuclear. To the regulatory body who licenced the facility, it means you're way behind the eight ball and out of control. Preventative Maintenance ( oil changes, tune ups etc.) good practice to inspect, record and advise engineers on the operating of the equipment which will help develop a best practice which is Predictive Maintenance - to rebuild equipment before failure by knowing the service life of the components and replacing before failure. Predictive Maintenance is where I like to perform now that I know what it is.

Replied by Kawboy on topic Cylinder Machining / Plateau Honing / Piston Cylinder Tolerances

We could write a book on this topic, literally.Excellent write up Kawboy.

There has long been a debate about the necessary surface finish for a cylinder after honing. In the 2 stroke word they managed to fit pistons and seat rings on mirror smooth chrome and nickle-chrome plating. Briggs and Stratton did it for decades that way. Yet engine builders would swear a corse hone was necessary or you could risk oil consumption. I never remember seeing a cross-hatch in a brand new OEM engine of any kind now that I think about it.

Some piston ring manufacturers will specify a surface finish and I would tend to follow thier requirements.

Another consideration is that the 1300, particularly the early ones had defective cylinder bores, they were put of round from day one, and some shops in an attempt to resolve oil consumption issues may have had better luck with a coarse hone. These bikes were usually rebuilt and I don't know if the dealer SOP was to re-hone and ring or bore the cylinders and fit oversized pistons. While this was known issue in 79 I don't think any knows how common or rare it was. I suspect it may have been pretty uncommon.

Like everything else in life, if you've done something in the past and succeeded, you don't need guidance to do it again. if you buy a new motorcycle, why would you need to look through the Operating Manual to learn how to operate your new motorcycle? Turn the key on, place the engine kill switch to run, set the choke, pull in the clutch and hit the start button. When warmed up, rock off the main stand, pull in the clutch, select first gear and pull away. Done it before. it's a no brainer.

Operating Manuals and Service Manuals are used for reference only. Nobody ever pulls out a manual unless they need more information that they don't have in their brain at the time. It's the curse of present society. We have no time to learn things to the point that we have a new saying as of 10 years ago. Multitasking- the performing of more than one task at the same time. I believe that the oil consumption issues of the 1979's could probably be justified by improper break in due to not following the instructions in the Operating Manual, The dealers selling the 1980-1989 models probably told the new owners that if they didn't follow the break in period to the letter, that any oil consumption problems would not be corrected with warranty, so .......

Back in the 1980's, when cars and motorcycles left the assembly plant, they would have left with break in oil installed which is a mineral oil without any friction modifiers to give the piston rings and cylinders a chance to break in. Many owners who spent $4000 of their hard earned money on a new toy, would change the engine oil and filter in as little as a100 miles to put in the best engine oil of their choice and that could contribute to failed break in.

Some new owners might for shits and giggles, just run a new engine up to redline just to find out how powerful their new toy was and that may have caused a failed break in.

Then there are the guys who find information on the internet suggesting different "better ways" to break in a new set of rings by running up a fresh rebuild warmed up engine to redline and then cutting the ignition and waiting for the engine to go cool, then repeating that 3 more times, then driving it the way you drive it because the rings have seated.

So many ways to fail a break in and cause damage (seized pistons) or glazed cylinders that won't allow the rings to seat etc. Tyler talked about chromium cylinders and Nickel Composite cylinders which would have had cast iron rings. Hard cylinder walls need soft rings to properly marry up. Very common practice in 2 stroke engines at that time during break in usually included an oil rich mixture for the first tank full (20:1), followed with a normal oil/fuel ratio (40:1)

Aftermarket ring manufacturers have many different finishing processes on the ring sealing surface and they require different cylinder honing processes to be followed along with proper break in periods in order for the rings to properly seat, So it's critical that both the engine rebuilder and the operator follow a "best practice" for success - Machining Instructions and Break In Instructions.

Instructions are not guidelines. They are specific "To Do" step by step direct orders to be followed. They are developed during engineering processes when designing a new process. As an operator or operator maintainer of a piece of equipment, Operating Manuals and Service Manuals are dumbed down to give minimum guidance to the reader in order to achieve success and not overly complicate the information to the point that the information is overwhelming and won't be followed.

Back in my 20's, I was a licenced mechanic and I was good at what I did. I was fast, efficient and seldom ever have a comeback for rework. Then I got a job in nuclear and got exposed to a higher level of maintenance. We were also expected to have an understanding of the engineering aspect of the equipment that we worked on and from that point in my life and going forward, came to realize just how shitty a mechanic I was years before. I did good work but didn't know shit from apples about what or why I was repairing cars. Repairing cars - Break down Maintenance - an unacceptable maintenance practice in nuclear. To the regulatory body who licenced the facility, it means you're way behind the eight ball and out of control. Preventative Maintenance ( oil changes, tune ups etc.) good practice to inspect, record and advise engineers on the operating of the equipment which will help develop a best practice which is Predictive Maintenance - to rebuild equipment before failure by knowing the service life of the components and replacing before failure. Predictive Maintenance is where I like to perform now that I know what it is.

Last edit: 1 year 1 week ago by Kawboy.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

- Offline

- Sustaining Member

-

Less

More

- Posts: 883

- Thank you received: 195

1 year 1 week ago #31734

by dcarver220b

Replied by dcarver220b on topic Cylinder Machining / Plateau Honing / Piston Cylinder Tolerances

Regarding 1979 A1 oil consumption. Mine used from day one, and yes, I followed mfrs break in process to the 'T'. Back in 79, I'd ask *every* owner about oil consumption, followed by a frown and large amount of use. Mine used 1/2 guart every tank full. It's possible, I suppose, that most every 79 owner didn't fastidiously follow break in procedures. Or that some mfr defect, undetected, processed a bunch of units with improper hone, clearance, roundness specs.

When I bought my 79, I had already built multiple 2 and 4 stroke single race bikes with no oil consumption problems. Also had built two Honda 750's with no problems for friends. So the Kawi really frustrated me. Kawasaki was no help. 'Within acceptable parameters'.

Regarding verbatim procedural compliance regarding service manuals.. Well, yes and no. Just because engineering spec's a mechanical device, it doesn't mean it's a) correct or b) the best spec possible due to financial, political, sales, new engineer on the job aspects. And it's my opinion that most service manuals are written by lower-educated (engineering wise) technical writers thus enabling higher paid engineers to work on the next killer project.

To prove this point, I can't think of *one* nuclear maintenance procedure at the power plant that's still on Rev 0.

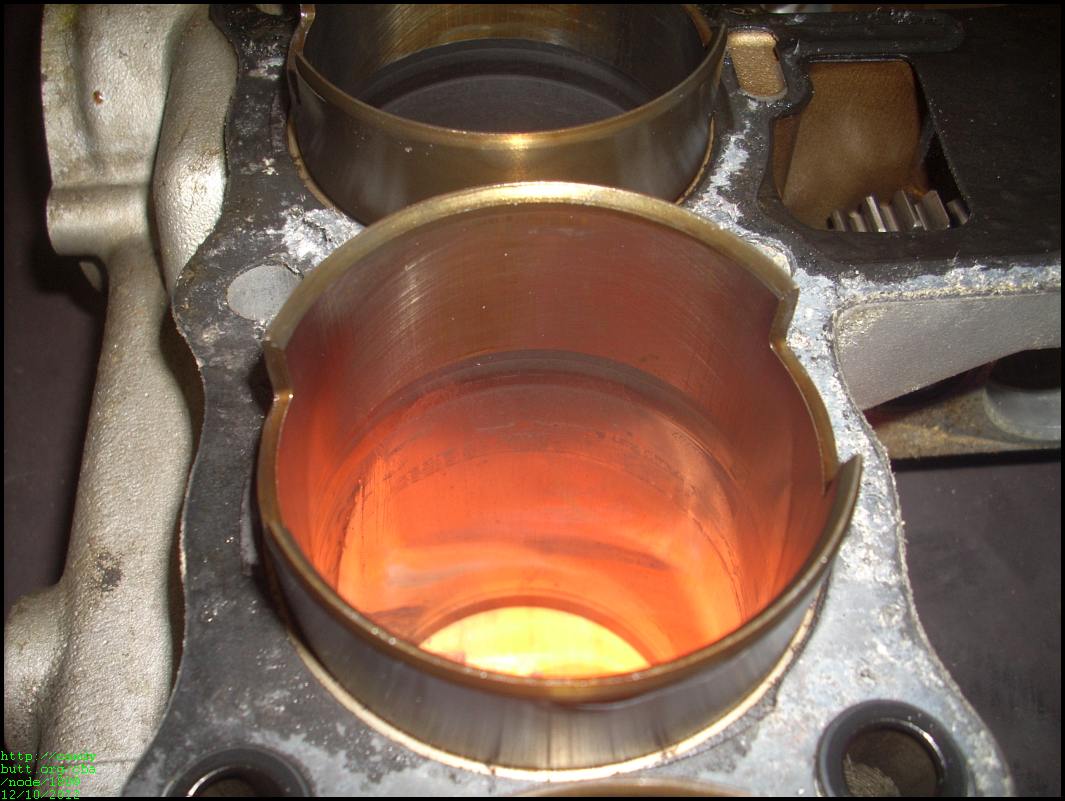

Here's a pic of mine after the 2013 rebuild.

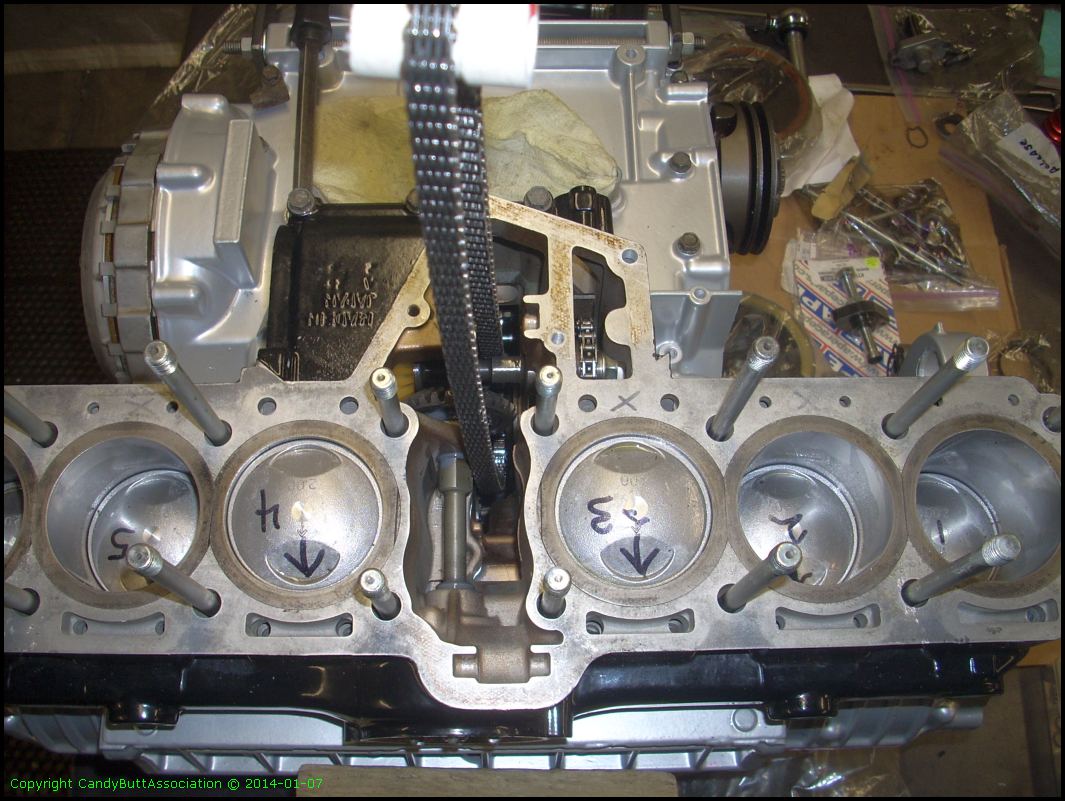

..and with pistons installed.. the cross-hatch is much less evident. Not sure, I didn't build it.

Like KB, I much prefer to operate in the Predictive Maintenance rather than Corrective Maintenance mode. Less money and headaches!

When I bought my 79, I had already built multiple 2 and 4 stroke single race bikes with no oil consumption problems. Also had built two Honda 750's with no problems for friends. So the Kawi really frustrated me. Kawasaki was no help. 'Within acceptable parameters'.

Regarding verbatim procedural compliance regarding service manuals.. Well, yes and no. Just because engineering spec's a mechanical device, it doesn't mean it's a) correct or b) the best spec possible due to financial, political, sales, new engineer on the job aspects. And it's my opinion that most service manuals are written by lower-educated (engineering wise) technical writers thus enabling higher paid engineers to work on the next killer project.

To prove this point, I can't think of *one* nuclear maintenance procedure at the power plant that's still on Rev 0.

Here's a pic of mine after the 2013 rebuild.

..and with pistons installed.. the cross-hatch is much less evident. Not sure, I didn't build it.

Like KB, I much prefer to operate in the Predictive Maintenance rather than Corrective Maintenance mode. Less money and headaches!

Please Log in or Create an account to join the conversation.

Time to create page: 0.139 seconds