- Posts: 883

- Thank you received: 195

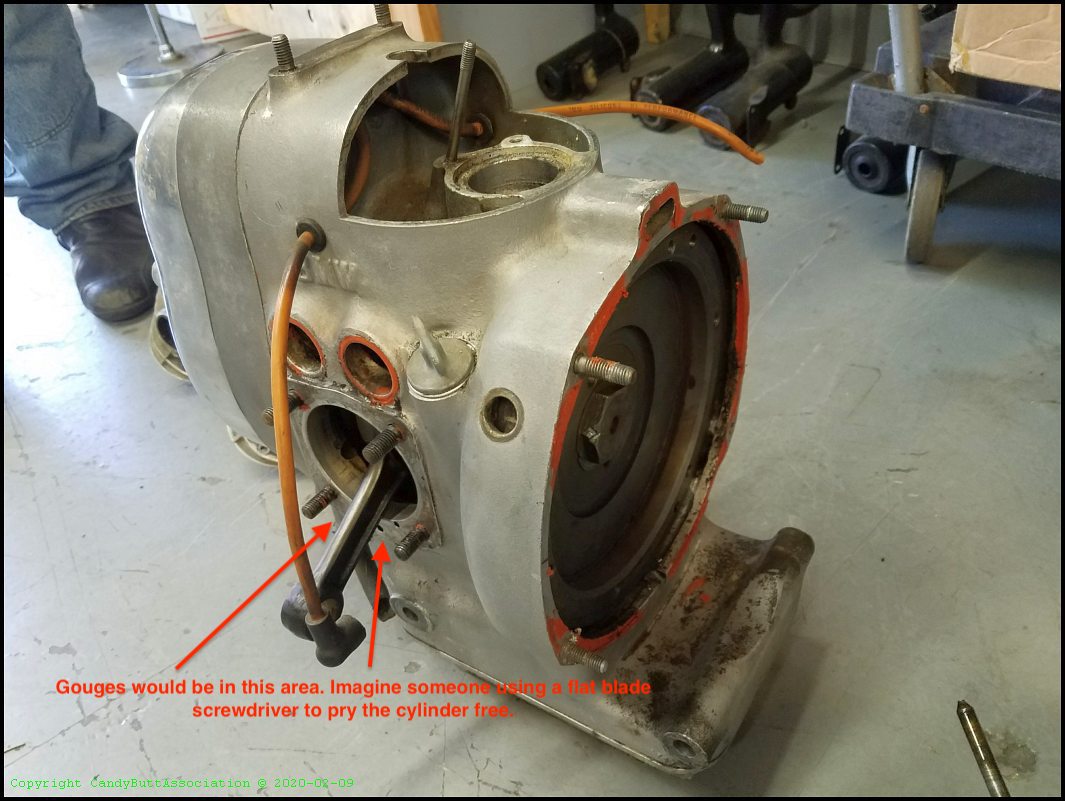

Repair gouge in aluminum block?

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Less

More

10 months 1 week ago #32106

by dcarver220b

Repair gouge in aluminum block? was created by dcarver220b

Somebody in the past must have used a screwdriver to free up my 1963 BMW R69s cylinder from the block. Resulted in a slight gouge. 32 raging horsepower.

Anyone have a repair technique that won't require massive disassembly? Yes, it would be best to strip down, weld it, machine it.

Instead, I'm looking at other repair... maybe some kind of metal epoxy (JB Weld or equivalent?) then work it smooth for a good sealing surface?

Found this stuff..

Tried a paper/metal gasket approximately same thickness as OEM but no happiness. Sadly, the engine was rebuilt by a very well known shop, who I won't name, and charged a ton o bucks. To bad it wasn't addressed then.

...and I'm the idiot who caused the damage. I was 18 years old, had a hammer, screwdriver, and zero knowledge. Of course, the bike was in the living room, so give me some street cred?

I'm even the 1d10T who used red rtv like it was cheap. Sigh. 18 years old, knew everything, just ask me?

TIA, D

Anyone have a repair technique that won't require massive disassembly? Yes, it would be best to strip down, weld it, machine it.

Instead, I'm looking at other repair... maybe some kind of metal epoxy (JB Weld or equivalent?) then work it smooth for a good sealing surface?

Found this stuff..

Tried a paper/metal gasket approximately same thickness as OEM but no happiness. Sadly, the engine was rebuilt by a very well known shop, who I won't name, and charged a ton o bucks. To bad it wasn't addressed then.

...and I'm the idiot who caused the damage. I was 18 years old, had a hammer, screwdriver, and zero knowledge. Of course, the bike was in the living room, so give me some street cred?

I'm even the 1d10T who used red rtv like it was cheap. Sigh. 18 years old, knew everything, just ask me?

TIA, D

Please Log in or Create an account to join the conversation.

- kawaBCN

-

- Offline

- Elite Member

-

Less

More

- Posts: 259

- Thank you received: 99

10 months 1 week ago #32107

by kawaBCN

RUN LIKE THE WIND¡¡¡

Replied by kawaBCN on topic Repair gouge in aluminum block?

What any mechanic in the late '60s would do for a lasting repair would be to weld with aluminum and a pass of rotaflex.

If you want to sell the motorcycle to the first person who comes, use epoxy paste.

If you want to sell the motorcycle to the first person who comes, use epoxy paste.

RUN LIKE THE WIND¡¡¡

Please Log in or Create an account to join the conversation.

- Kawboy

-

- Offline

- Sustaining Member

-

Less

More

- Posts: 3129

- Thank you received: 1098

10 months 1 week ago #32109

by Kawboy

Replied by Kawboy on topic Repair gouge in aluminum block?

You all know I was a pipefitter / welder and I carried a ticket in Aluminum welding TIG. Unless it was a chunk broken out of the cylinder or casing I wouldn't weld it.

First- Aluminum has a porous grain structure and unless it is virgin aluminum, it will absorb all kinds of contaminants. Once it's heated in a welding process, the contaminants will float to the surface and become porosity in the weld. The TIG process is an AC weld process and during the time that the arc is under positive half of the arc the contaminants try to jump the arc and solidify on the tungsten tip of the welding. We call this the cleaning half of the arc. At some point, the tungsten electrode becomes so contaminated that the arc starts to wander uncontrollably and that's a problem. So you have to stop, then break off the end of the tungsten tip that's contaminated, then strike the tungsten tip under a DC- arc on a piece of copper to reform a ball on the end of the tungsten, then switch back to AC and continue welding. Every time you stop and start the molten puddle on the part, more distortion happens. I've been asked to weld broken cylinder fins on cylinders a number of times and I can say that fighting those welds would make an alcoholic out of a teatotaler.

Second- You have to ask "under what circumstances is the joint needing to seal?" I'll assume the problem is either the engine casing or the cylinder and it's a gasket seal with no differential pressure across the face of the seal to speak of. If the gasket face was exposed to either engine oil pressure or coolant pressure, maybe welding and resurfacing would be more appropriate but if it's just the difference between crankcase pressure and atmosphere, then something like JB weld will be more than sufficient.

Third- Is it a cosmetic appearance issue? I have welded up stator covers that got a "road rash" in a crash and after welding and cleaning up / polishing, there was a difference in color between the parent metal and the filler metal, the filler metal being brighter.

Finally- I had a Ford F350 that I used to pull a 35ft fifth wheel RV trailer and I opted to put in a 60 gallon auxiliary fuel tank in the truck box. That aluminum checker plated tank developed a crack around the outlet fitting at the bottom of the tank so when the tank was full, there was a fuel head pressure of 2 ft. Now being a welder with a $3000 welding machine (Thermal Arc 180) I knew I could repair it but it wouldn't be easy. Soaked in diesel fuel for the past 6 years, I could try to bake out the contaminants as best as possible and attempt to weld it or what the Hell, try the JB weld first and if it holds great. If it doesn't, no harm, no foul, just grind it out and weld it. So I emptied the tank and cleaned up the area with Lacquer Thinner and applied the JB weld. 2 days later, I filled the tank and it was holding. Another 5 years later and I traded in the truck and that tank was still sealed fine. This was my first experience with JB Weld and I had my doubts until after this experience.

First- Aluminum has a porous grain structure and unless it is virgin aluminum, it will absorb all kinds of contaminants. Once it's heated in a welding process, the contaminants will float to the surface and become porosity in the weld. The TIG process is an AC weld process and during the time that the arc is under positive half of the arc the contaminants try to jump the arc and solidify on the tungsten tip of the welding. We call this the cleaning half of the arc. At some point, the tungsten electrode becomes so contaminated that the arc starts to wander uncontrollably and that's a problem. So you have to stop, then break off the end of the tungsten tip that's contaminated, then strike the tungsten tip under a DC- arc on a piece of copper to reform a ball on the end of the tungsten, then switch back to AC and continue welding. Every time you stop and start the molten puddle on the part, more distortion happens. I've been asked to weld broken cylinder fins on cylinders a number of times and I can say that fighting those welds would make an alcoholic out of a teatotaler.

Second- You have to ask "under what circumstances is the joint needing to seal?" I'll assume the problem is either the engine casing or the cylinder and it's a gasket seal with no differential pressure across the face of the seal to speak of. If the gasket face was exposed to either engine oil pressure or coolant pressure, maybe welding and resurfacing would be more appropriate but if it's just the difference between crankcase pressure and atmosphere, then something like JB weld will be more than sufficient.

Third- Is it a cosmetic appearance issue? I have welded up stator covers that got a "road rash" in a crash and after welding and cleaning up / polishing, there was a difference in color between the parent metal and the filler metal, the filler metal being brighter.

Finally- I had a Ford F350 that I used to pull a 35ft fifth wheel RV trailer and I opted to put in a 60 gallon auxiliary fuel tank in the truck box. That aluminum checker plated tank developed a crack around the outlet fitting at the bottom of the tank so when the tank was full, there was a fuel head pressure of 2 ft. Now being a welder with a $3000 welding machine (Thermal Arc 180) I knew I could repair it but it wouldn't be easy. Soaked in diesel fuel for the past 6 years, I could try to bake out the contaminants as best as possible and attempt to weld it or what the Hell, try the JB weld first and if it holds great. If it doesn't, no harm, no foul, just grind it out and weld it. So I emptied the tank and cleaned up the area with Lacquer Thinner and applied the JB weld. 2 days later, I filled the tank and it was holding. Another 5 years later and I traded in the truck and that tank was still sealed fine. This was my first experience with JB Weld and I had my doubts until after this experience.

Please Log in or Create an account to join the conversation.

- dcarver220b

-

Topic Author

Topic Author

- Offline

- Sustaining Member

-

Less

More

- Posts: 883

- Thank you received: 195

10 months 1 week ago #32112

by dcarver220b

Found this stuff at Amazon and ordered it up. I have a chunk of aluminum, will replicate the gouges (I know the guy who put the first ones in) then see how well it fills, sands, and cleans up. Might even contaminate the surface with oil first, then clean, then fill and 'machine'. Just a test. Come to think of it, I just might have a Japanese engine case from a cb150 laying around...

Replied by dcarver220b on topic Repair gouge in aluminum block?

I believe this is the case, no pun intended. There might be some crankcase pressure due to pistons in downstroke, but this engine vents directly to atmosphere with what appears to be about a 12mm vent pipe. At a whopping 9.5:1 with new pistons, cylinders, and rings, blow by should be minimal.I'll assume the problem is either the engine casing or the cylinder and it's a gasket seal with no differential pressure across the face of the seal to speak of.

Found this stuff at Amazon and ordered it up. I have a chunk of aluminum, will replicate the gouges (I know the guy who put the first ones in) then see how well it fills, sands, and cleans up. Might even contaminate the surface with oil first, then clean, then fill and 'machine'. Just a test. Come to think of it, I just might have a Japanese engine case from a cb150 laying around...

Please Log in or Create an account to join the conversation.

Time to create page: 0.122 seconds