I tend to go off in to analytical spurts when working through a problem so here I go-The “situation” here is black deposits on the spark plugs after running for a couple of hundred miles that starts to cause misfiring. The black deposits are dry I assume since a wire brush will clean up the plugs and the misfiring stops. My conclusion here would be that the engine is running fuel rich and the black deposits are carbon from unburned fuel. Had the deposits been black, wet and shiny, a wire brush would not clean them off to the point that misfiring stopped. Black, wet, shiny deposits would be an oil consumption problem.

Spark plugs-A well running KZ1300 runs fine on BPR6ES plugs and that is the engineered standard for this engine. Altering from the standard for any reason is a work around to alleviate repairing a problem with a poor running engine. Only under extreme running conditions like full out racing, should it be necessary to run a colder plug by probably one heat range. Running a hotter plug is a workaround for burning off oil deposits to save having to do a ring job or valve seal replacement, but be careful and don’t spend a lot of time at wide open throttle. You risk detonation from the spark plugs getting so hot they glow. The engineering standard for the spark plugs was created back in 1979. This engine is also a wasted spark ignited engine and after the last year of production (1989) a newer design spark plug was created specifically for wasted spark ignited engines and that is the double platinum or double iridium plug.

A wasted spark system has one spark plug firing from the center electrode to the ground electrode and the second spark plug on that ignition coil fires from the ground electrode to the center electrode completing the circuit. In a conventional firing ignition system, the spark travels from the center electrode to the ground electrode and during this process, molecules from the center electrode got oxidized and we had erosion of the center electrode. Iridium or platinum tipped plugs extended the life of the spark plugs by 5 or 10-fold so the cost of the upgraded spark plugs was justified by the extended intervals between changing plugs.

In wasted spark systems, half of the spark plugs firing backwards to the conventional i.e. firing ground to center electrode now have ground electrode erosion, so the plug manufacturers elected to offer double platinum or double iridium plugs to accommodate this new erosion situation.

So, bottom line for me- if you choose to upgrade to a better long-lasting spark plug, then opt for a double platinum or double iridium plug in the same heat range as the BPR6ES and at $18 a plug, this recommendation would only be for a correct running engine. If you’re dealing with oil fouling or fuel fouling, deal with that first before opting for the more expensive plugs.

Running rich- If It weren’t for the Keihin BSW 32 carbs on this bike half the topics and half of the posts wouldn’t be on the site. I blamed most of the issues on fuel management lack of understanding and Ethanol now found in 98% of all available fuel. Carburetors made of aluminum and zinc suffer the most and what we end up dealing with is aluminum oxide and or zinc oxide blocking passages, jets and binding of moving parts.Scotch’s flushing tool has helped a lot of our members with shellac deposits caused by leaving fuel in the carburetors for extended periods and the fuel vaporizing off gradually leaving behind the shellac. Some of the oxides may get flushed out but from what I’ve seen, the bond of the oxide to the base metals needs to be mechanically removed, very carefully. What’s really special about Scotch’s Cleaning Tool is the ability to reverse flush the Low Speed circuit and I’ll get to that later.Things that cause carbs to run rich

Carb float Level- The float level will affect all of the different circuits if not correctly set Above all else, first confirm that the float levels are within specs.Carb float needle seat O-rings- The needle seat has an O-ring sealing the seat to the carb body. The original spec’d O-rings were Buna N and that was fine for gasoline. Ethanol blended gasoline causes Buna-N to shrink which could allow fuel to circumvent around the seal between the float seat needle and carb body causing flooding of the carbs over long periods of sitting. Upgrading to Viton O-rings overcomes the issue created by the Ethanol.

Choke plungers not fully seated. This could happen if the plungers are binding in the carb body or the plunger actuating mechanism is not set up properly.

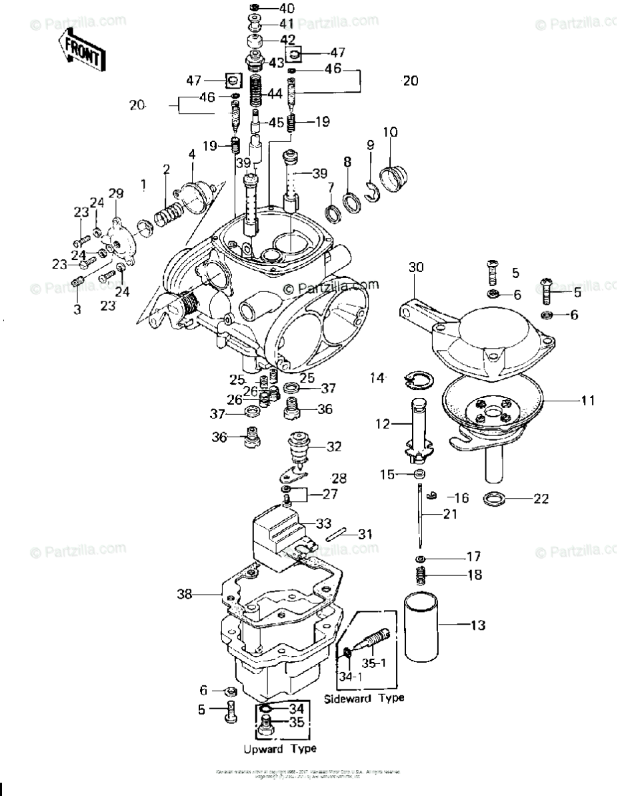

Needle jets with plugged emulsion ports (item #39 in diagram). There are 16 emulsion ports in each needle that are roughly .010” in diameter. These ports allow air in to the needle jets to help break up the droplets of fuel before the fuel enters to carb throat. If the ports are plugged, more fuel will be pulled in to the carb throat and cause rich running. I doubt that most of the members on the site who decided to overhaul their carbs actually pulled out the needle jets and had a good look at them. To remove, you need to remove the main jets and brass washer, and have the piston valves (item #13) removed, then push the needle jets out through the carb throats (towards the top of the carb). All 6 of my needle jets had numerous ports plugged completely with the white oxide. I had to run number drill bits through the holes to clean out then I also used Autosol metal polish to clean the jets up to an as new appearance. Be careful not to open up the emulsion ports beyond original size.

Enrichment Valve seized in the carb body. The Enrichment Valve works in conjunction with the Low-Speed Circuit and sends a rich mixture down the intake ports under deacceleration. I experienced 3 stuck enrichment valves on my 3 carburetors. Scotch came up with a mod to eliminate the Enrichment System and has had great results. Consider doing the mod.

Regarding the Pilot adjusting screws-The Pilot Adjusting screws and the Pilot jets are the main components of the Low-Speed Circuit. I like to think of the Low-Speed Circuit as a miniature super rich carb and by opening up the pilot screws, you introduce more fuel/air in to the Low-Speed Circuit. Now the Low-speed Circuit only functions between Idle and around 2,000 RPM. The Main circuit operates between 1,500 RPM and top end, so there’s a cross over point between the 2 circuits. If the engine stumbles when blipping the throttle from idle to 4,000 RPM, then the issue is probably with the transition ports in the carb throats at the butterfly plates, location. There are 3 transition ports that are well known for plugging and Scotch’s cleaning Tool was specifically designed to flush these ports out in reverse flow to the standard flow of the Low-Speed Circuit. The only way to clear these plugged ports is by reverse flowing a cleaning fluid through the transition ports, pushing the blockage out. Scotch’s Tool is superb in design for doing this and I can’t say enough about it.